ADAS are technological features designed to improve driver safety and prevent accidents. They use sensors like radar, sonar, lidar, and cameras to perceive the environment around the vehicle and provide critical information to the driver or take automatic actions to avoid or mitigate crashes.

These systems aim to increase safety by reducing the number and severity of accidents. According to a study by the AAA Foundation, ADAS has the potential to prevent 40% of vehicle crashes, 37% of injuries, and 29% of vehicular deaths.

The main types of ADAS calibration are generally categorized into two broad categories. In some vehicle types, both calibrations are required.

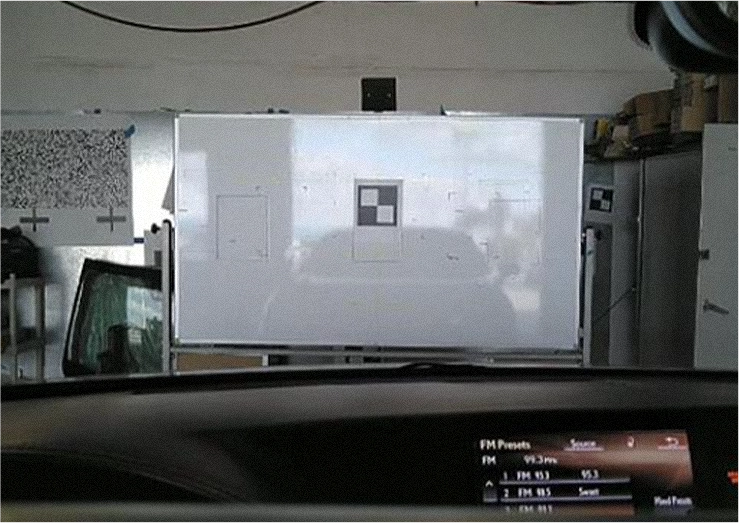

Performed with the vehicle stationary. Involves using specialized equipment and calibration targets or patterns. Used after sensor or camera replacement, repairs, or realignment. Ensures sensors and cameras are correctly aligned relative to the vehicle's chassis.

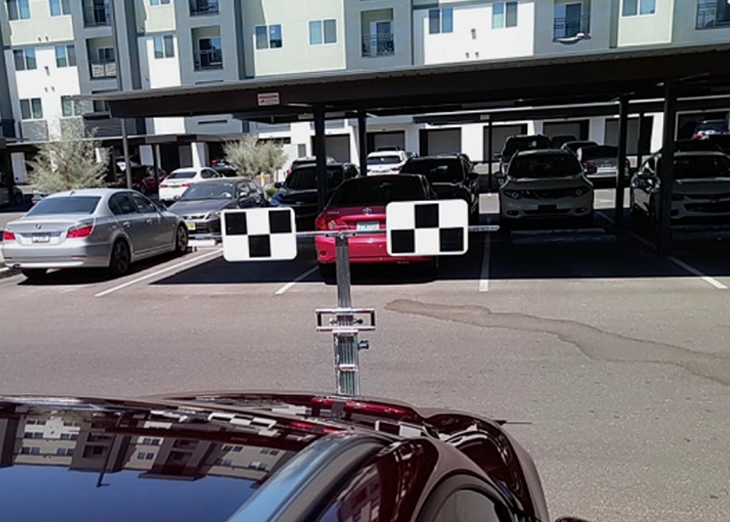

Performed with the vehicle in motion. Involves driving the vehicle on specific routes or scenarios. Used for features like adaptive cruise control, lane keep assist, etc. Ensures sensors and cameras function correctly in real-world driving conditions.

Your ADAS systems need recalibration after certain repairs or modifications to ensure they continue protecting you and your passengers.

When sensors, cameras, radar modules, or lidar are replaced or repaired. To ensure proper alignment and functioning.

If the vehicle has been involved in a collision that impacts sensor mounts or the vehicle's frame. Realignment is necessary for accurate system operation.

When suspension components or wheel alignments are adjusted or replaced. Ensures sensors and cameras are correctly calibrated relative to the vehicle's chassis.

Repairs that affect the vehicle's frame or body structure, which may impact sensor alignment.

Especially if the windshield has cameras or sensors mounted on or near it. Proper calibration ensures the sensors' accuracy.

Diagnostic trouble codes (DTCs) indicate calibration may be needed.

Some manufacturers recommend routine recalibration or checks as part of regular maintenance to ensure continued accuracy.

Accurate ADAS calibration requires controlled, repeatable environmental conditions. Even small disruptions in lighting or background setup can cause sensors to misread or fail entirely. Below are some of the most common environmental factors that lead to calibration failures:

All calibrations at TRUE ADAS Solutions Canada are performed in a controlled lighting environment with neutral backgrounds, ensuring sensor accuracy, target clarity, and repeatable precision — every time.

Operates in a dedicated, well-lit, climate-controlled, and clutter-free environment. Ensures optimal conditions for precise sensor and camera calibration.

Utilizes the latest calibration tools, software, and equipment that meet or exceed OEM standards. Incorporates both static and dynamic calibration methods for comprehensive coverage.

Staff are trained and certified by OEMs and industry recognized bodies. Continual education on the latest ADAS technologies and calibration techniques.

Uses manufacturer-specific, up-to-date calibration protocols. Ensures calibration accuracy and maintains vehicle warranty compliance.

Prioritizes precise calibration to ensure ADAS features function correctly, enhancing safety. Performs thorough vehicle inspection and sensor cleaning before calibration.

Meets industry standards and adheres to safety regulations. Recognized by automotive tools manufacturers and industry associations.

Transparent processes and detailed reports provided to customers. Offers warranties or guarantees on calibration quality.

Fast turnaround times without compromising quality.

Our comprehensive 7-step calibration procedure ensures precision and safety

Record calibration details, including date, technician, vehicle information, and calibration results, for warranty and future reference.

Contact us today to schedule your appointment with our certified technicians